1. Material: 17CrNiMo6; 18CrNiMo7-6; 20CrNi2Mo

2. Certificate: ISO, ABS, CCS, BV,KR, etc

3. Length: Max: 16m

4. Weight: Max: 23t

5. Process: Forging- heat treatment- machining

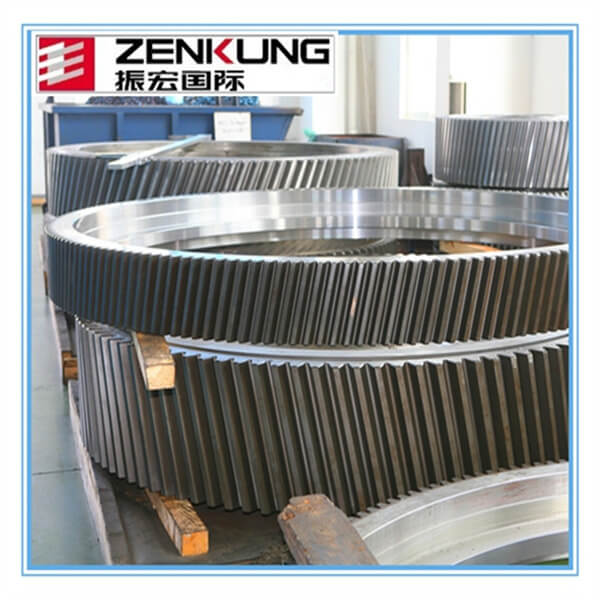

1. Product Name: Open die forging gear shaft

2. Raw Material:

Carbon steel, C-Mn steel, alloy structure steel, alloyed tool steel, cold roll steel, steel for pressure vessel, carburizing steel, die steel, stainless steel and so on.

| Wind Turbine Shaft | 42CrMo4, 34CrNiMo6 |

| Marine Shaft | C-Mn steel |

| Hydro Turbine Shaft | 20SiMn |

| Roller Shaft | 70Cr3Mo; 9Cr2Mo; MC1; MC2; MC3 |

| Gear Shaft | 17CrNiMo6; 18CrNiMo7-6; 20CrNi2Mo; 42CrMo; 47CrNiMo6, 20CrMnMo |

| Gear | 17CrNiMo6; 18CrNiMo7-6; 20CrNi2Mo; 42CrMo; 47CrNiMo6, 20CrMnMo, 30 CrNiMo6 |

| Pressure Vessel Forgings | SA105, SA350 LF2, 16Mn, 20MnMo, 15MnMo, 12Cr2Mo1, 14Cr1Mo, 42CrMo, F304, F316, 17-4PH, 4330, 4336, 4340 |

| Ring Rolling | 16Mn, 50Mn, 42CrMo, 15MnV, 35CrMo, A105, 20#, 304, 304L, 316, 316L |

* As we manufacture customized products, other materials are also appreciated.

3. Specification:

1) The maximum outside diameter: 2,800 mm;

2) The maximum height: 800mm;

3) The maximum weight: 33t.

* The products could be manufactured according to your request.

4. Standard: ASTM, ASME, DIN, AISI, JIS and EN;

5. Certification:

ISO 9001:2008, PED Certificate, TUVRheinland, Bureau Veritas (BV), Lloyd Register (LR), ABS, RINA, Germanischer Lloyd (GL), Korean Register of Shipping (KR), Det Norske Veritas (DNV), Nippon Kaiji Kyokai (NK);

6. Foreign Customers:

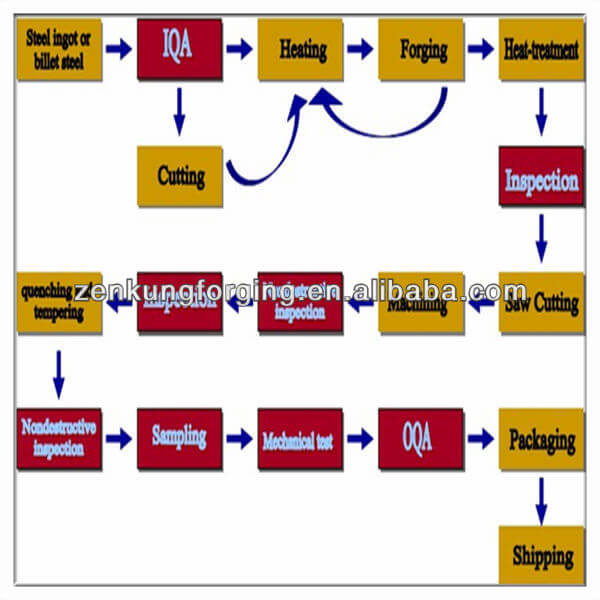

7. Production Process:

Forging---heat treatment---machining (rough machining and finish machining)

8. Delivery Status:

N+T (Normalizing + Tempering), Q+T (Quenching + Tempering);

9. Production Capacity: 30000 ton per year;

10. Application: It is mainly used in mining machinery;

11. Price:

* The price does not contain quenching and tempering cost. If the process is required, the price will be added. Specific price is determined by the material and your specific requirements.

Advantages:

1. Good mechanical properties;

2. High tensile strength;

3. Well-closed formation;

4. Comparative price;

5. High-quality production;

6. Customized services, manufacturing according to your specific requirements.

Production Flow Chart

Equipments

Testing Instruments

Certificates

Packing

Company Environment

Contact:

Jiangyin Zenkung Forging Co., Ltd.

Address: Xuxiang, Shuxin, Longsha Industrial Zone, Huaxi, Jiangyin City, Jiangsu Province

Tel: +86 510 86215950

Fax: +86 510 86218523