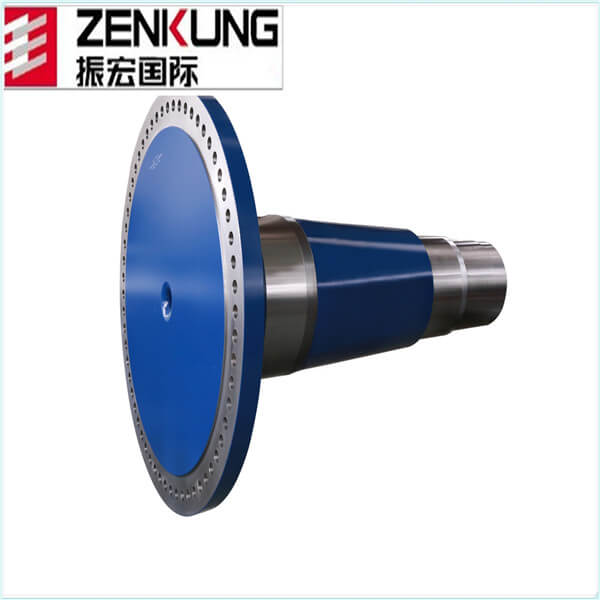

Cusotmized forged wind turbine shaft wind generator part :

1.Type: wind turbine shaft

2.Material: steel

3.Weight: about 8t

4.Production ability: 0.75MW-3MW

5.Maximum weight: 23t

6.Application: used in wind power generation

7.Technics: forged

8.Main production process: forged+ heat treatment+ rough machining+finish machining

9.Standards: ASTM, ASME, DIN, JIS, ISO, BS, API, EN

|

Length:

|

|

|

Diameter:

|

|

Cusotmized forged wind turbine shaft wind generator part

1.Type: wind turbine shaft

2.Material: 34CrNiMo6

3.Weight: about 8t

4.Production ability: 0.75MW-3MW

5.Maximum weight: 23t

6.Application: used in wind power generation

7.Technics: forged

8.Main production process: forged+ heat treatment+ rough machining+finish machining

9.Standards: ASTM, ASME, DIN, JIS, ISO, BS, API, EN

10.Certifications: ISO9001:2008,TUVRheinland, Bureau Veritas (BV), Lloyd Register (LR), ABS, RINA, Germanischer Lloyd (GL), Korean Register of Shipping (KR), Det Norske Veritas (DNV), Nippon Kaiji Kyokai (NK),PED.

11.Additional information: usually delivered in finished machining condition for this kind of product(delivery status:Quenching+Tempering)

The centerpiece of 34CrNiMo6 wind turbine shaft

Superiority

1.High precision of dimensional tolerance

2.Excellent mechanical property

3.Available in varities of dimensions (acc to customer's requirements)

4.Advanced production equipments and test instruments

5.42 excellent technicist

6.strictly control the production procedures

7.also pay more attention to the protection and packaging

The centerpiece of 34CrNiMo6 wind turbine shaft

34CrNiMo6 wind turbine shaft

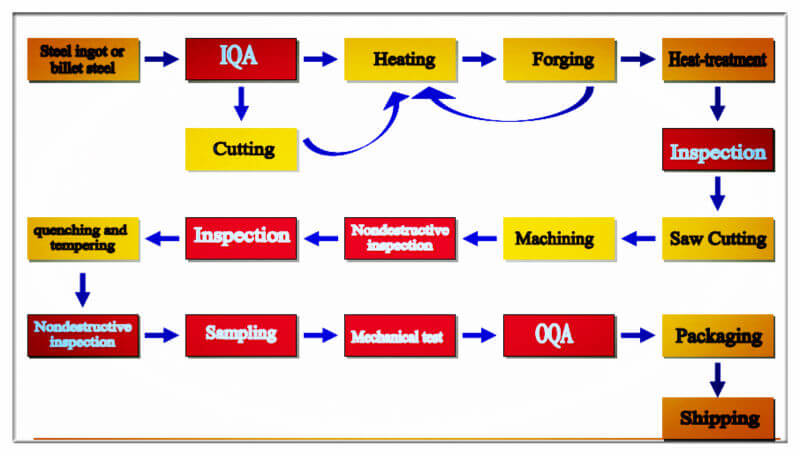

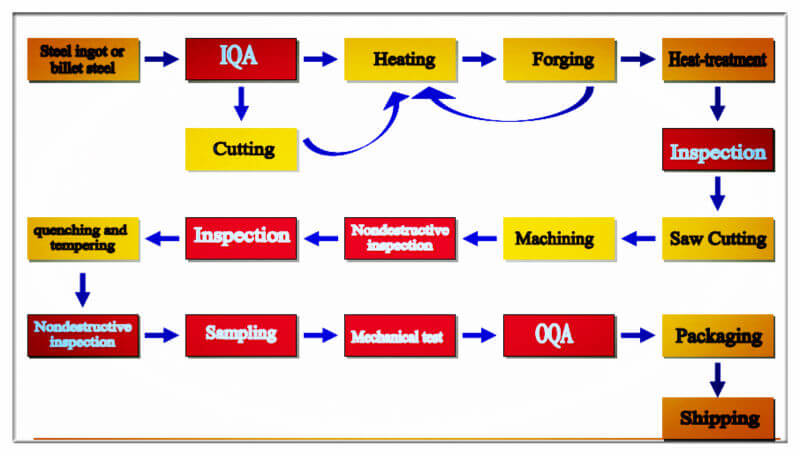

Production Flow Chart

The centerpiece of 34CrNiMo6 wind turbine shaft

Main Production Equipments

The centerpiece of 34CrNiMo6 wind turbine shaft

1. 2000T oil hydraulic press. (Peak pressure of 2000 tons)

2. 4,000 mm ring rolling mill. Domestically advanced NC ring-rolling mill ensures production of ring pieces of the best quality.

3. 4500T oil hydraulic press

4. Natural gas machine pallet furnace

5. Final machining department(C63200C*6/40,CK61200/6M,CKD61200E/6M)

6. Digital control lathes

7. There are many kinds of model horizontal lathe, C61160 x 16/32, C61200 x 12/32 and C61200 x 14/40

8. There are many kinds of model vertical lathes, C52500/32, C52315, etc.

34CrNiMo6 wind turbine shaft

Test Instruments

34CrNiMo6 wind turbine shaft

Certificates

34CrNiMo6 wind turbine shaft

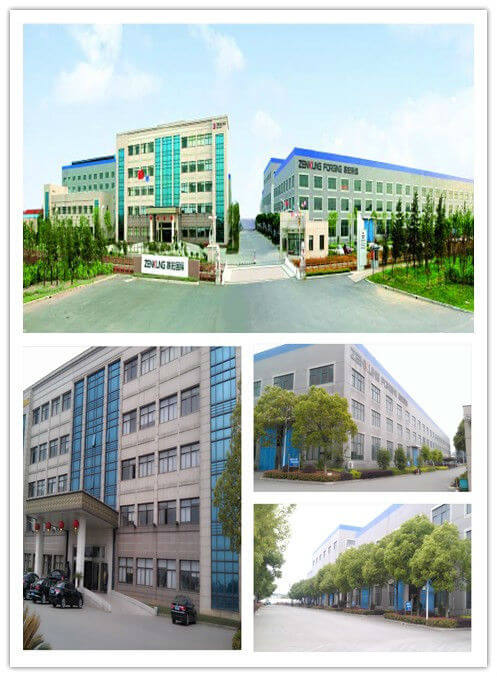

Factory Overlook

10.Certifications: ISO9001:2008,TUVRheinland, Bureau Veritas (BV), Lloyd Register (LR), ABS, RINA, Germanischer Lloyd (GL), Korean Register of Shipping (KR), Det Norske Veritas (DNV), Nippon Kaiji Kyokai (NK),PED.

11.Additional information: usually delivered in finished machining condition for this kind of product(delivery status:Quenching+Tempering)

The centerpiece of 34CrNiMo6 wind turbine shaft

Superiority

1.High precision of dimensional tolerance

2.Excellent mechanical property

3.Available in varities of dimensions (acc to customer's requirements)

4.Advanced production equipments and test instruments

5.42 excellent technicist

6.strictly control the production procedures

7.also pay more attention to the protection and packaging

The centerpiece of 34CrNiMo6 wind turbine shaft

34CrNiMo6 wind turbine shaft

Production Flow Chart

The centerpiece of 34CrNiMo6 wind turbine shaft

Main Production Equipments

The centerpiece of 34CrNiMo6 wind turbine shaft

1. 2000T oil hydraulic press. (Peak pressure of 2000 tons)

2. 4,000 mm ring rolling mill. Domestically advanced NC ring-rolling mill ensures production of ring pieces of the best quality.

3. 4500T oil hydraulic press

4. Natural gas machine pallet furnace

5. Final machining department(C63200C*6/40,CK61200/6M,CKD61200E/6M)

6. Digital control lathes

7. There are many kinds of model horizontal lathe, C61160 x 16/32, C61200 x 12/32 and C61200 x 14/40

8. There are many kinds of model vertical lathes, C52500/32, C52315, etc.

34CrNiMo6 wind turbine shaft

Test Instruments

34CrNiMo6 wind turbine shaft

Certificates

34CrNiMo6 wind turbine shaft

Factory Overlook

Note:

We factory produce different dimensions of shafts used in wind power generation(requested by customers). We also have other products, such as vessel shaft, gear shaft, flange, wheel gear,gear ring,etc. Any free forgings, ring forgings and special-shaped ring forgings are possible.We wish to be your trusting supplier in the long term.(http://zenkungforging.en.alibaba.com)